Inspiring the Next Generation of Florida Manufacturers Starts with MFG Day Student Tours

Since 2012, MFG DAY/Month has grown across the nation. A central focus of the celebration is to introduce Advanced Modern Manufacturing to young people in order to attract them to careers in the industry. If Florida, FLATE and its many partners that include regional professional and business associations, Workforce and Economic development organizations, educational institutions of all levels have organized student tours and other events to celebrate the industry and introduce the community, especially students, to manufacturing and its many great careers. It’s time to plan for MFG DAY/month in FL 2018.

Since 2012, MFG DAY/Month has grown across the nation. A central focus of the celebration is to introduce Advanced Modern Manufacturing to young people in order to attract them to careers in the industry. If Florida, FLATE and its many partners that include regional professional and business associations, Workforce and Economic development organizations, educational institutions of all levels have organized student tours and other events to celebrate the industry and introduce the community, especially students, to manufacturing and its many great careers. It’s time to plan for MFG DAY/month in FL 2018.

I encourage ALL manufacturers to host student tours. 100% of the feedback we have gotten over the past 5 years from company hosts is incredibly positive: that the tours were a good investment of time and energy; their own workforce was jazzed by experience of having student visitors, and a few had direct hires. The vast majority said it was also great for company morale. Overall, its been all great! Here is what you need to get started:

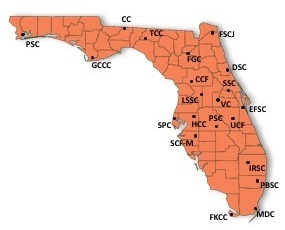

- In most areas of the state, there are regional coordinators, you can find a pretty up to date list of these folks here:

- Coordinators do their best to help identify a middle or high school for you.

- PLAN!

- Most tours happen on MFG DAY, Oct 5. If that day doesn’t work for you or your school, no worries, you tour can be any day in October (Mfg Month!) [We all get more publicity if a bunch of tours happen on the same day, so many areas try to have most of the tours on the official date.}

- Most tours happen in the middle of the day (10-1:30) to take advantage of school buses for transportation. Many coordinators work directly with the school district, which schedules the buses and covers the cost of the buses.

- Provide lunch (pizza/drinks), inside or outside if at all possible. This is a great time for employees to connect with students AND for students to complete a short tour survey that FLATE will provide (and will tally as well). Allow 30 min.

- Review FLATE’s “Tour Tips” to maximize your impact.

- Plan the tour, engage your employees. You don’t have to show it all.

- Post your tour on mfgday.com – and let everyone know about your event.

- Report your tour info to FLATE (mbarger@hccfl.edu).

- Invite the press, local officials, etc to share the opportunity.

FLATE provides a number of resources for Manufacturing Day in Florida. In an effort to make a statewide impact, we have developed and posted teacher lesson plans (to help prepare students for tours), outreach materials like special MFG DAY – FL logos; classroom poster, graphic for MFGDAY-FL 2018 t-shirts, web buttons & banners, how to booklets and handouts, recorded webinars about these resources, and more. All resources can be found on FLATE’s wiki: www.flate.pbwiki.com – look for the tour and MFGDAY button to access these free resources. FLATE also has posted the Florida student tour surveys as an online survey or downloadable pdf files. There are also links to surveys for company hosts and educators /parents accompanying students.

We want to keep Florida on the national manufacturing map as an active and enthusiastic participants. Its time to get start planning your student tour and other activities or events.

If you are new to MFGDAY in Florida (or even if you are not new), don’t hesitate to contact us at FLATE with any questions.

The terms Mechatronics and Vacuum Technology represent 20th Century state-of-the-art “tags” for leading edge STEM based skill sets that are even more significant in this 21st century digital world. Mechatronics was coined in the 1960’s to verbalize the then brand new integration of mechanical and electronic knowledge for commercial (automobiles, etc), space (moon mission) and defense (ICB’s) applications. Vacuum Technology could trace its heritage to the 19th Century (Edison’s work with incandescent filaments for example) but certainly is anchored in technology development (radio and television) in the 1920’s and cemented in all advanced technologies triggered during and post Manhattan Project. Although there is always a tendency to rebrand almost everything (IHOP to IHOB for the latest example), new identifiers for either of these incredibly STEM based skill sets is not necessary. What is important is to recognize that from a technician’s perspective both are indicative of the required and similar advanced knowledge and skills for today’s advanced manufacturing sector technicians.

The terms Mechatronics and Vacuum Technology represent 20th Century state-of-the-art “tags” for leading edge STEM based skill sets that are even more significant in this 21st century digital world. Mechatronics was coined in the 1960’s to verbalize the then brand new integration of mechanical and electronic knowledge for commercial (automobiles, etc), space (moon mission) and defense (ICB’s) applications. Vacuum Technology could trace its heritage to the 19th Century (Edison’s work with incandescent filaments for example) but certainly is anchored in technology development (radio and television) in the 1920’s and cemented in all advanced technologies triggered during and post Manhattan Project. Although there is always a tendency to rebrand almost everything (IHOP to IHOB for the latest example), new identifiers for either of these incredibly STEM based skill sets is not necessary. What is important is to recognize that from a technician’s perspective both are indicative of the required and similar advanced knowledge and skills for today’s advanced manufacturing sector technicians. FLATE is now beginning an initiative to build a community of practice that supports vacuum technology and its overlapping Mechatronics skills. The National Science Foundation Advanced Technological Education program (NSF-ATE) is supporting FLATE activities focused on technician education that lead to careers in advanced manufacturing that depend on vacuum technology and science skills and knowledge. FLATE has entered into a partnership with the American Vacuum Society (AVS) to identify the essential skills that are and will be essential to support this industry sector. (The AVS is the internationally recognized premiere organization of academic, industry, Department of Defense, National Laboratory, and NASA STEM professionals that require or use controlled pressure environments to accomplish their missions.) This objective will be reached through a joint effort by the AVS Education Committee, Normandale Community College in Bloomington, MN, and FLATE. The work has already begun at workshop supported by AVS at the Colorado School of Mines that took place in early June. Stay tuned for the next steps in this project in the fall of 2018. For more information, contact

FLATE is now beginning an initiative to build a community of practice that supports vacuum technology and its overlapping Mechatronics skills. The National Science Foundation Advanced Technological Education program (NSF-ATE) is supporting FLATE activities focused on technician education that lead to careers in advanced manufacturing that depend on vacuum technology and science skills and knowledge. FLATE has entered into a partnership with the American Vacuum Society (AVS) to identify the essential skills that are and will be essential to support this industry sector. (The AVS is the internationally recognized premiere organization of academic, industry, Department of Defense, National Laboratory, and NASA STEM professionals that require or use controlled pressure environments to accomplish their missions.) This objective will be reached through a joint effort by the AVS Education Committee, Normandale Community College in Bloomington, MN, and FLATE. The work has already begun at workshop supported by AVS at the Colorado School of Mines that took place in early June. Stay tuned for the next steps in this project in the fall of 2018. For more information, contact  The recommendations released come from three years’ worth of research and feedback from more than 10,000 Floridians in each of Florida’s 67 counties as part of the Florida 2030 initiative- a multi-million research initiative that seeks to identify the challenges and opportunities Florida has between now and 2030, and to create a blueprint for Florida’s future. Recommendations found that:

The recommendations released come from three years’ worth of research and feedback from more than 10,000 Floridians in each of Florida’s 67 counties as part of the Florida 2030 initiative- a multi-million research initiative that seeks to identify the challenges and opportunities Florida has between now and 2030, and to create a blueprint for Florida’s future. Recommendations found that: FLATE, FloridaMakes, the Able Trust, Economic Development organizations and Educational institutions gathered to hear the specific recommendations for Talent and Education Pilar of Project 2030 at the recent Earners to Learners Summit held in Tampa. In addition to the project recommendations, Commissioner Pam Stewart presented the Commissioners Business Recognitions Awards during the event. These awards to a number of exemplary programs and businesses around the state. The award winners are posted here:

FLATE, FloridaMakes, the Able Trust, Economic Development organizations and Educational institutions gathered to hear the specific recommendations for Talent and Education Pilar of Project 2030 at the recent Earners to Learners Summit held in Tampa. In addition to the project recommendations, Commissioner Pam Stewart presented the Commissioners Business Recognitions Awards during the event. These awards to a number of exemplary programs and businesses around the state. The award winners are posted here:  October 5 marks the official kick off for Manufacturing (MFG) Day with industry tours, open houses, career fairs and other miscellaneous events being planned in Florida and across the country.

October 5 marks the official kick off for Manufacturing (MFG) Day with industry tours, open houses, career fairs and other miscellaneous events being planned in Florida and across the country. Every year, the Florida Advanced Technological Center-FLATE, helps middle school students by mentoring in their Engineering Capstone projects. The 8th grade STEM students are tasked to exhibit technical expertise to solve challenging problems by producing ideas and products that have the potential to be marketed in the real world.

Every year, the Florida Advanced Technological Center-FLATE, helps middle school students by mentoring in their Engineering Capstone projects. The 8th grade STEM students are tasked to exhibit technical expertise to solve challenging problems by producing ideas and products that have the potential to be marketed in the real world. Engineering Capstone Project- Lead The Way (PLTW), another project supported by FLATE, provides a comprehensive approach to STEM Education. Through activity, projects, and problem-based curriculum, PLTW gives students in high school a chance to apply what they know, identify problems, find unique solutions, and lead their own learning. The implementation of this program provides tools to empower students and transform the classroom into a collaboration space where content comes to life.

Engineering Capstone Project- Lead The Way (PLTW), another project supported by FLATE, provides a comprehensive approach to STEM Education. Through activity, projects, and problem-based curriculum, PLTW gives students in high school a chance to apply what they know, identify problems, find unique solutions, and lead their own learning. The implementation of this program provides tools to empower students and transform the classroom into a collaboration space where content comes to life.

This month FLATE had the opportunity to visit two two-year advanced manufacturing and mechatronics programs in Virginia: Piedmont Virginia Community College (PVCC) in Charlottesville and Virginia Western Community College in Roanoke (VWCC). PVCC was hosting an outreach event for high school programs to introduce the students to their new program launched this academic year. Over one hundred twenty juniors and seniors from 4 regional high schools arrived at the college for a 10 am program start. After welcome from the program director and dean, a lively panel of local manufacturing and production employers talked to the young people about their companies and what they make. They went on to talk about the kinds of skills new employees need to have to be hire and successful in their companies. The business sectors represented all voiced the need for some common fundamental technical skills like measurements, electronics and quality. They also strongly endorsed the need for personal success skills (employability skills, soft skills, personal skills, etc). After the lively discussions and questions from the audience, the students cycled through four stops: manufacturing lab tour and program information; company displays where they showcased their products and individually talked about their technician workforce needs. Several high school and college engineering student projects were also on display. The last two stops were hands on activities building a small ball bearing system and wiring a LED light circuit. It was a great opportunity to get ideas for effective outreach and benchmark the labs of our Florida Engineering Technology programs, and hear about the workforce needs of manufacturing companies in other states and regions.

This month FLATE had the opportunity to visit two two-year advanced manufacturing and mechatronics programs in Virginia: Piedmont Virginia Community College (PVCC) in Charlottesville and Virginia Western Community College in Roanoke (VWCC). PVCC was hosting an outreach event for high school programs to introduce the students to their new program launched this academic year. Over one hundred twenty juniors and seniors from 4 regional high schools arrived at the college for a 10 am program start. After welcome from the program director and dean, a lively panel of local manufacturing and production employers talked to the young people about their companies and what they make. They went on to talk about the kinds of skills new employees need to have to be hire and successful in their companies. The business sectors represented all voiced the need for some common fundamental technical skills like measurements, electronics and quality. They also strongly endorsed the need for personal success skills (employability skills, soft skills, personal skills, etc). After the lively discussions and questions from the audience, the students cycled through four stops: manufacturing lab tour and program information; company displays where they showcased their products and individually talked about their technician workforce needs. Several high school and college engineering student projects were also on display. The last two stops were hands on activities building a small ball bearing system and wiring a LED light circuit. It was a great opportunity to get ideas for effective outreach and benchmark the labs of our Florida Engineering Technology programs, and hear about the workforce needs of manufacturing companies in other states and regions. My second visit was to Virginia Western Community College (VWCC) located in Roanoke, VA. The mechatronics degree at VWCC was started by and still let by program manager Dan Horine about ten years ago. The program has grown to well over 100 students and has attracted a number of manufacturers to the region. After visiting the mechatronics, computer aided drafting and “Fab” lab, I was lucky to observe the following required mechatronics systems course: ENG 105 – Problem Solving in Engineering Technology:

My second visit was to Virginia Western Community College (VWCC) located in Roanoke, VA. The mechatronics degree at VWCC was started by and still let by program manager Dan Horine about ten years ago. The program has grown to well over 100 students and has attracted a number of manufacturers to the region. After visiting the mechatronics, computer aided drafting and “Fab” lab, I was lucky to observe the following required mechatronics systems course: ENG 105 – Problem Solving in Engineering Technology: You can find out more by visiting the colleges’ websites:

You can find out more by visiting the colleges’ websites:

On November 9, 2017, FLATE partnered with the

On November 9, 2017, FLATE partnered with the  All the panelists emphasized that employees, up and down the company’s organizational chart

All the panelists emphasized that employees, up and down the company’s organizational chart To this end, we developed credentialed-based articulations to the A.S. Engineering Technology (A.S.E.T.) to give full credit for a number of credentials thereby accelerating the time completion. This pathway model has been adopted in many disciplines and at many college across the nation. Now in 2017 I am excited to share the work done at Daytona State College (DSC) to establish a statewide articulation for all A.S.E.T. graduate in any of the 10 specializations at over 20 state and community colleges to the B.S. Engineering Technology (B.S.E.T.) that will go into effect early in 2018. This sounds like a “no-brainer” because there are many smooth “2+2” Associate of Arts (A.A.) to Bachelors of Arts or Science (B.A. or B.S.) degree. However, technical degrees for which the main focus is prepare students to enter specific technical jobs upon completion not necessarily to continue to a bachelor’s degree. Additionally, there are critical criteria that must be met for baccalaureate degrees that are set by institutional accrediting agencies, state governing boards, and discipline-specific accrediting organizations (in the case for Engineering and Engineering Technology, that organization is ABET (

To this end, we developed credentialed-based articulations to the A.S. Engineering Technology (A.S.E.T.) to give full credit for a number of credentials thereby accelerating the time completion. This pathway model has been adopted in many disciplines and at many college across the nation. Now in 2017 I am excited to share the work done at Daytona State College (DSC) to establish a statewide articulation for all A.S.E.T. graduate in any of the 10 specializations at over 20 state and community colleges to the B.S. Engineering Technology (B.S.E.T.) that will go into effect early in 2018. This sounds like a “no-brainer” because there are many smooth “2+2” Associate of Arts (A.A.) to Bachelors of Arts or Science (B.A. or B.S.) degree. However, technical degrees for which the main focus is prepare students to enter specific technical jobs upon completion not necessarily to continue to a bachelor’s degree. Additionally, there are critical criteria that must be met for baccalaureate degrees that are set by institutional accrediting agencies, state governing boards, and discipline-specific accrediting organizations (in the case for Engineering and Engineering Technology, that organization is ABET ( An additional challenge, and perhaps magic for (for those of us who live in education domain is the fact that the B.S.E.T. at DSC can be taken remotely with online and hybrid courses. The hybrid courses have four options for completing the hands-on lab exercises: 1) Complete the exercises at Daytona State in the college labs; 2) Purchase a lab kit for the course sold through the Daytona State bookstore; 3) arrange to do the lab portions at the local A.S.E.T. degree-offering state or community colleges; or 4) arrange to complete the lab activities at a workplace with a designated proctor. This generates many degrees of freedom for students but all of these options support efficient pathways to the B.S.E.T. degree.

An additional challenge, and perhaps magic for (for those of us who live in education domain is the fact that the B.S.E.T. at DSC can be taken remotely with online and hybrid courses. The hybrid courses have four options for completing the hands-on lab exercises: 1) Complete the exercises at Daytona State in the college labs; 2) Purchase a lab kit for the course sold through the Daytona State bookstore; 3) arrange to do the lab portions at the local A.S.E.T. degree-offering state or community colleges; or 4) arrange to complete the lab activities at a workplace with a designated proctor. This generates many degrees of freedom for students but all of these options support efficient pathways to the B.S.E.T. degree. Interested in the B.S.E.T. degree, please contact Dr. Ron Eaglin at Daytona State College (

Interested in the B.S.E.T. degree, please contact Dr. Ron Eaglin at Daytona State College (